This text was obtained via automated optical character recognition.

It has not been edited and may therefore contain several errors.

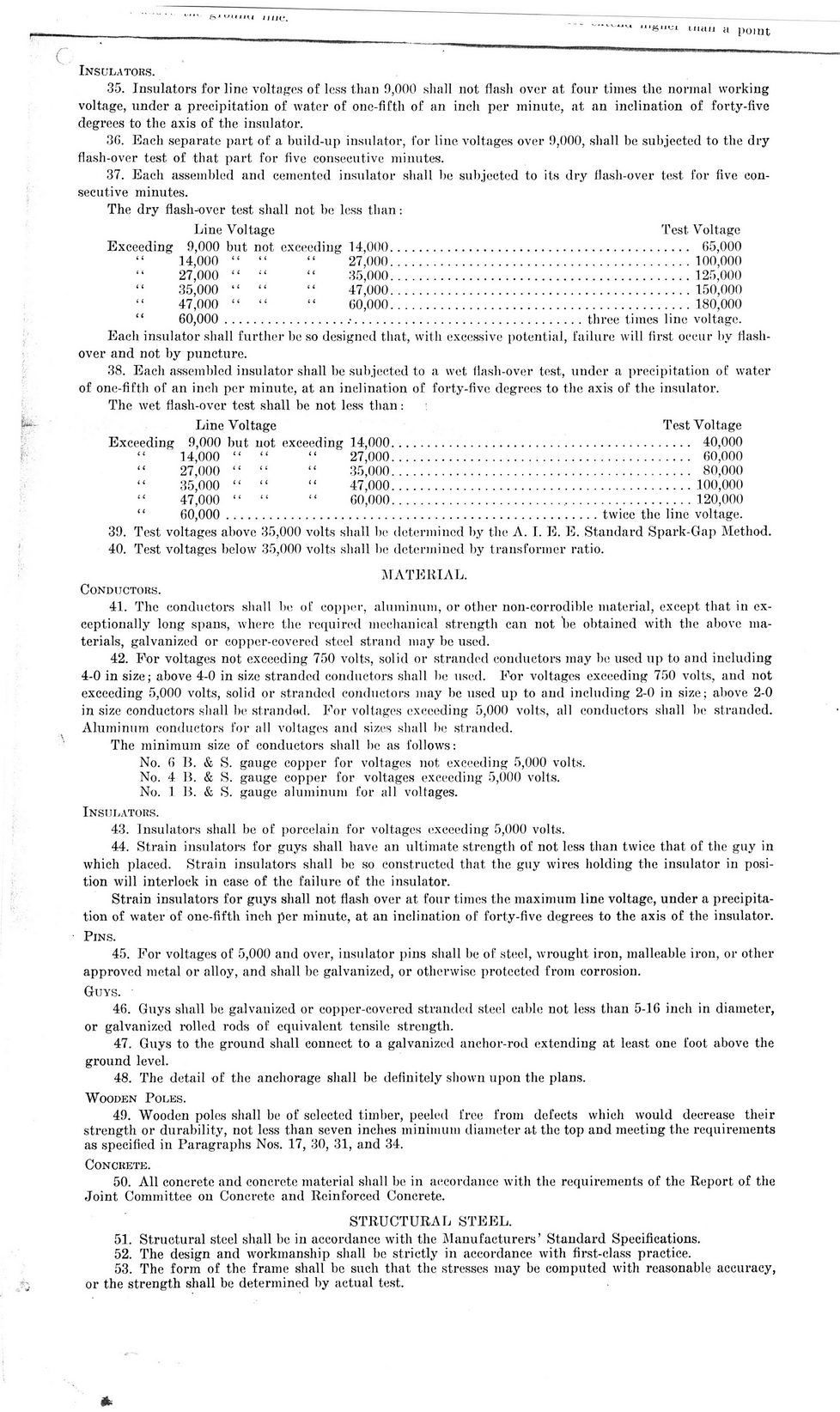

?'v"? I'luiu a point Insulators. 35. Insulators for line voltages of less than 9,000 shall not flash over at four times the normal working voltage, under a precipitation of water of one-fifth of an inch per minute, at an inclination of forty-five degrees to the axis of the insulator. 36. Each separate part of a build-up insulator, for line voltages over 9,000, shall be subjected to the dry flash-over test of that part for five consecutive minutes. 37. Eacli assembled and cemented insulator shall be subjected to its dry flash-over test for live consecutive minutes. The dry flash-over test shall not be less than: Line Voltage Test Voltage Exceeding 9,000 but not exceeding 14,000....................................................... 65,000 14.000 ? ? ? 27,000...................................................... 100,000 27.000 ? ? 35,000...................................................... 125,000 35.000 ? ? ? 47,000...................................................... 150,000 47.000 ? ? ? 60,000...................................................... 180,000 ? 60,000 .....................?........................................three times line voltage. Each insulator shall further be so designed that, with excessive potential, failure will first occur by flash-over and not by puncture. 38. Each assembled insulator shall be subjected to a wet (lash-over test, under a precipitation of water of one-fifth of an inch per minute, at an inclination of forty-five degrees to the axis of tlie insulator. The wet flash-over test shall be not less than: Line Voltage Test Voltage Exceeding 9,000 but not exceeding 14,000....................................................... 40,000 14.000 ? ? ? 27,000..................................................... 60,000 27.000 ? ? ? 35,000..................................................... 80,000 35.000 ? 11 ? 47,000..................................................... 100,000 47.000 ? ? ? 60,000..................................................... 120,000 ? 60,000 ...............................................................twice the line voltage. 39. Test voltages above 35,000 volts shall be determined by the A. I. E. E. Standard Spark-Gap Method. 40. Test voltages below 35,000 volts shall be determined by transformer ratio. MATERIAL. Conductors. 41. The conductors shall be of copper, aluminum, or other non-corrodible material, except that in exceptionally long spans, where the required mechanical strength can not be obtained with the above ma- terials, galvanized or copper-covered steel strand may be used. 42. For voltages not exceeding 750 volts, solid or stranded conductors may be used up to and including 4-0 in size; above 4-0 in size stranded conductors shall be used. For voltages exceeding 750 volts, and not exceeding 5,000 volts, solid or stranded conductors may be used up to and including 2-0 in size; above 2-0 in size conductors shall be strandod. For voltages exceeding 5,000 volts, all conductors shall be stranded. Aluminum conductors for all voltages and sizes shall be stranded. The minimum size of conductors shall he as follows: No. 6 B. & S. gauge copper for voltages not exceeding 5,000 volts. No. 4 B. & S. gauge copper for voltages exceeding 5,000 volts. No. 1 B. & S. gauge aluminum for all voltages. Insulators. 43. Insulators shall be of porcelain for voltages exceeding 5,000 volts. 44. Strain insulators for guys shall have an ultimate strength of not less than twice that of the guy in which placed. Strain insulators shall be so constructed that the guy wires holding the insulator in position will interlock in case of the failure of the insulator. Strain insulators for guys shall not Hash over at four times the maximum line voltage, under a precipitation of water of one-fifth inch per minute, at an inclination of forty-five degrees to the axis of the insulator. Pins. 45. For voltages of 5,000 and over, insulator pins shall be of steel, wrought iron, malleable iron, or other approved metal or alloy, and shall be galvanized, or otherwise protected from corrosion. Guys. 46. Guys shall be galvanized or copper-covered stranded steel cable not less than 5-16 inch in diameter, or galvanized rolled rods of equivalent tensile strength. 47. Guys to the ground shall connect to a galvanized anchor-rod extending at least one foot above the ground level. 48. The detail of the anchorage shall be definitely shown upon the plans. Wooden Poles. 49. Wooden poles shall be of selected timber, peeled free from defects which would decrease their strength or durability, not less than seven inches minimum diameter at the top and meeting the requirements as specified in Paragraphs Nos. 17, 30, 31, and 34. Concrete. 50. All concrete and concrete material shall be in accordance with the requirements of the Report of the Joint Committee on Concrete and Reinforced Concrete. STRUCTURAL STEEL. 51. Structural steel shall be in accordance with the Manufacturers? Standard Specifications. 52. The design and workmanship shall be strictly in accordance with first-class practice. 53. The form of the frame shall be such that the stresses may be computed with reasonable accuracy, or the strength shall be determined by actual test. *

Gainesville R.R L&n-Railroad-and-Ice-Light-and-Bottling-Works-Contract-(1921)-3